fruit and vegetable dryer machine dehydrator for herbs IKE

Company Advantages

1. drying oven shows excellent characteristics of fruit and vegetable dryer machine materials.

2. Its quality is highly evaluated by authoritative testing organizations.

3. Through years of development in drying oven industry, have a certain degree of industry competitiveness.

4. Supported by the industry's knowledgeable technicians and customer service team, IKE wins great reputation since founded.

AIO-S1500G multi-function all-in-one dehydrating system is suitable for drying a very large variety of food. Such as: fruit drying, meat drying, vegetable drying, tobacco drying, hemp drying, and so on.

SPECIFICATIONS FOR AIO-S1500G Multi-Function All-in-one Dehydrating System | ||

Main performance parameters | Materials | Stainless Steel |

Capacity | 1000kg~1500kg per batch | |

Power Supply | 380~3Nv/50Hz/60Hz | |

Power Input | 17.0KW | |

Running Current | 30.0A | |

Fast heating-up | 6.0KW | |

Maximum Power | 24.0Kw | |

Dehydration Amount | 45.0Kg/h ( @ 50℃,80%) | |

Working Temperature | 50~80℃ | |

Noise Level | ≤75dB(A) | |

Wind Volume | 23500m³/h | |

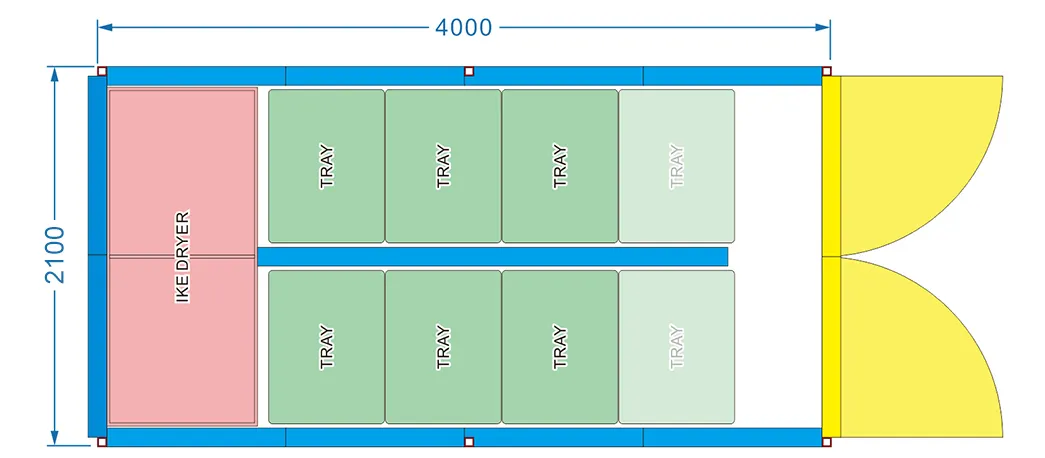

Machine Dimension(L*W*H) | 4000*2100*2100mm | |

Lead time | 10~30 working days | |

Payment terms | 1, We can offer different pricing of FOB, CIF and C&F. | |

Shipping | 1, We offer FOB Guangzhou and FOB Shenzhen to our customers. | |

Warranty | Two-years warranty after AIO-S1500G ship | |

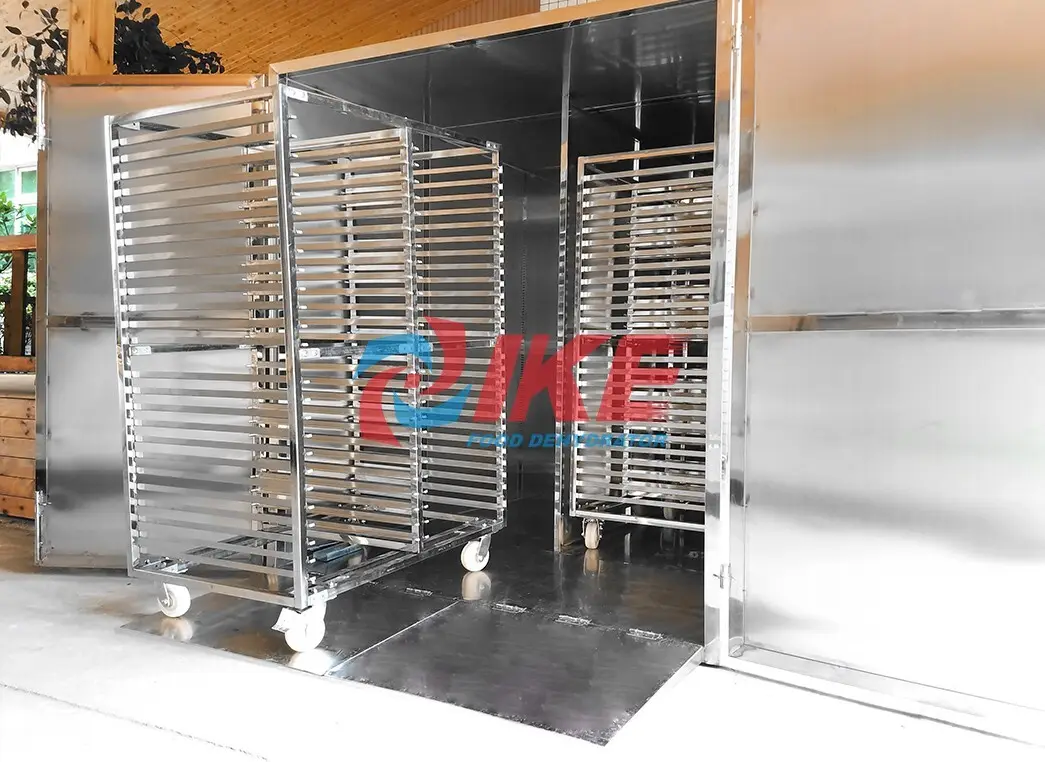

IKE AIO-S1500G is our new multi-function all-in-one dehydrating system IKE specially designed and manufactured for today’s customers. It made of stainless steel. It uses S-1500G as main drying machine. It is the most convenient all-in-one drying machine that has the highest capacity. It is made with stainless steel and can be equipped with plastic, stainless steel or customized drying racks. The machine is ready to use once connected to a power outlet. If your application requirements may not be met by our type AIO-S1500G dehydrating system, we will be all too glad to offer guidance, design, and manufacture of a customized drying system. Just contact us!

AIO-S1500G multi-function all-in-one dehydrating system

AIO-S1500G multi-function all-in-one dehydrating system wit stainless steel trolley

AIO-S1500G multi-function all-in-one dehydrating system with plastic trays.

Door handle

AIO-S1500G with main machine S-1500G

The AIO-S1500G multi-Function dehydrating system is an all-in-one drying machine. Customers do not need to install the machine. Connect to the power supply to use. Plastic trays, stainless steel trays and custom shelves are available in dehydrating system. The AIO-S1500G is the largest and most convenient all-in-one drying machine.

Top view

Company Features

1. is at the dominant position thanks to the excellent quality drying oven .

2. Through continuous complementing R&D and technology innovation, food drying machine now ranks top in this market.

3. Relying on professional team and advanced technology, IKE has the great dream to be the leading meat dryer machine manufacturer in the future. Call! IKE will constantly adjust itself to adapt to customer's requirements. Call!

IKE: Smart Drying, Industry Defining.

Your Trusted Commercial and Industrial Food Dehydrator Manufacturer, Specializing in High-Quality Drying Solutions Since 1994.

Quick Links

product

contact us