Customized Conveyor Mesh Belt Large Food Dehydrator1

-

v s

- IKE is equipped with professional sales and customer service staff. They are able to provide services such as consulting, customization and product selection.

1. The manufacturing process of IKE drying line proceeds as follows: the procurement of raw materials, parts and components processing, plating and anodizing, complete mechanical assembly, and testing.

2. The product is not prone to high vibration environment. Thanks to its heavy-duty construction, it can effectively resist any kind of impact.

3. A complete marketing vein of drying line has been formed by Guangdong IKE Industrial Co.,Ltd..

4. It has good economic value with a wide market prospect.

IKE customized conveyor mesh belt large food dehydrator is automatic continuous drying machine for large-scale production. The continuous drying machine can be equipped according to the user’s requirement and the production demands. It is suitable for drying a very large variety of food. Such as noodles, dehydrated vegetables for instant noodles, fruits, seafood, and so on. Contact us for free drying testing!

Model | Unit | WRH-1200AL | WRH-1200GL |

Power supply | V/Hz | 380V-3N / 50Hz | 380V-3N / 50Hz |

Power input | Kw | 13.0 | 13.0 |

Running current | A | 20 | 20 |

Fast heating-up | Kw | 9.0 | 9.0 |

Maximum Power | Kw | 24 | 24 |

Dehumidification amount | Kg/h | 40 | 36 |

Best Drying Temperature | ℃ | 50~65 | 50~80 |

Max. hot air Temperature | ℃ | 65 | 80 |

Working Ambient temperature | ℃ | 5~40 | 5~40 |

Noise Level | dB(A) | ≤ 72dB | ≤ 72dB |

Wind volume | m³/h | 4000m*2+2200*4 | 4000m*2+2200*4 |

Machine Dimension(L*W*H) | Mm | 1250*800*1920 | 1250*800*1920 |

Gross Weight | kg | 390 | 390 |

Different Models can be customized based on requirment

Model | Unit | Flow Lines |

Power Supply | V/Hz | 380V~3N/50Hz |

Power Input | Kw | 0.1-8.0kw variable frequencies to adjust |

Maximum Current | A | 10 |

Maximum Power Consumption | Kw | 8.0 |

Layer Number |

| 1-10 layers to choose |

Operation Speed | m/min | 0m/min-2m/min to adjust |

Chain Width | m | 1.0-6.0 to choose |

Chain Material |

| 201, 304, 316 stainless steel to choose |

Chain Length per layer | m | 1.5m-12m to choose |

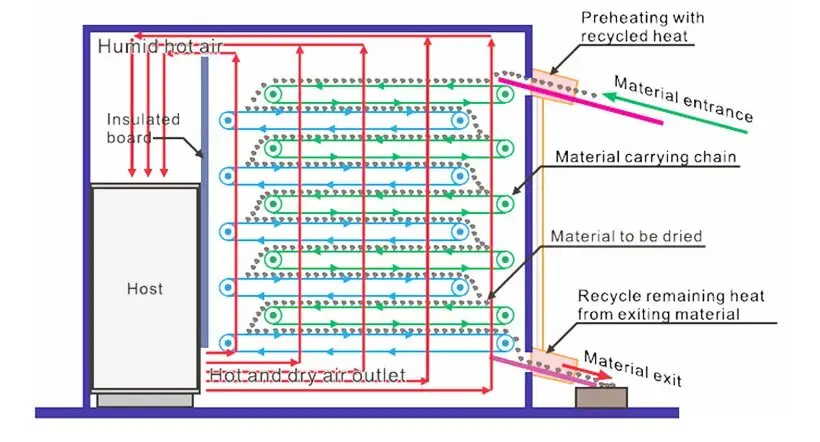

The automatic belt food dehydrator uses air to transfer heat and remove moisture as the food moves through multiple temperature zones on a conveyor bed. By adding rotary feeding device, the evenly spreading can be realized, and as there are no drops during drying. The balanced drying can be ensured. The dried food will be automatically discharged to a collector.

The running speed of the conveyer belt can be adjusted according to the food character.

1. Middle and low temperature dehumidification drying

The IKE customized conveyor mesh belt large food dehydrator drying fruits and vegetables in 50℃~80℃, articles does no damage, no moldy and maintain nutrition.

2. Use heat pump technology

The IKE customized conveyor mesh belt large food dehydrator with high efficiency through the use of a heat pump system for removing air humidity.

3. Working in wholly sealed drying system, hygiene and energy conservation

Drying in a closed sealed system, no foreign material pollution. Efficiency is irrelevant to external environment, that can maintain high energy efficiency at all seasons. No hot air and water vapor loss maximize energy recovery.

4. Running Stable, operating easily

Graphical touch control system, automatic intelligent control and demands no human duty after setting.

Company Features

1. Guangdong IKE Industrial Co.,Ltd. specializes in R&D and production of drying line and is popular among customers.

2. The perseverance in the implementation and application of superb technology is conducive to the development of IKE.

3. It is our determination to create IKE to be the leading stainless steel conveyor belt manufacturer. Inquire now! Based on the policy of drying equipment , IKE strives to be a more competitive enterprise. Inquire now! Constant innovation is indispensable for long-term development of Guangdong IKE Industrial Co.,Ltd.. Inquire now! Customers can be totally assured of our quality and after-sale service for metal conveyor belt . Inquire now!

IKE: Smart Drying, Industry Defining.

Your Trusted Commercial and Industrial Food Dehydrator Manufacturer, Specializing in High-Quality Drying Solutions Since 1994.

Quick Links

product

contact us